The Co-bots are coming, and they're here to help

Robotics is set to be a $226 billion dollar industry by 2021, just 5 years from now. There are no statistics on exactly how much of that industry is healthcare related but there is some scattered research out there. For example, Medgadget tells us that surgical robotics systems will be a $6.4 billion dollar industry by 2020, and the exoskeleton robot market is to reach over $2 billion by 2021. Robotics and Automation News reports that “half of all surgeries in some countries are now done with robots.” Other aspects of healthcare using robotics include nursing and assistance to the elderly and those with disabilities. Biotech manufacturing uses robotics (IFR reports that by 2019, more than 1.4 million new industrial robots will be installed in factories around the world) and even biotech R&D has begun trying them out. The Financial Times reports how GlaxoSmithKline in the UK is using “co-bots to work side by side with scientists at research facilities.”

Robotics Looks to the Deep Sea for Biotech R&D

This past September MedTechPulse compiled a great slideshow “9 Ways Robots Are Getting So Much Better”. I recognized a few of these robots, as they had come out of the Boston/Cambridge biotech cluster – no surprise here. Research institutes such as The Wyss Institute in Cambridge, Massachusetts are creating their own robots, but they're not the kind that will clean your house. Instead, these robots have been created to stretch the limits of what we can accomplish in surgery, internal medicine and tissue engineering.

What Does an Octopus-Inspired Robot Do (And Why Create It)?

This past summer Harvard University’s Wyss Institute created one of the cutest robots you’ll ever see, in the shape of an octopus. Their inspiration to create a robot using this shape was due to an octopus’ “ability to perform great feats of strength and flexibility, despite lacking an internal skeletal system”. The team at Wyss did a 180 on how robots are thought of (as made of hard components). What a soft robot can do is utilize "fuel" in a very different way. Softness also promises these benefits: “Soft robotic grippers are already being used to handle undersea structures in scientific research. One can easily envision soft robots being used to handle fragile objects such as crops, or even living beings. Internal medicine and wearable devices are also likely areas for future soft robots.” And did I mention that this robot was 3-D Printed?

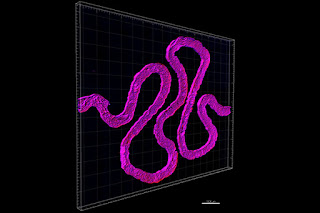

Rat + Robot = Stingray

Wyss Institute’s Kevin Kit Parker, in his quest to eventually build a human heart, was inspired by the jellyfish and stringrays that he and his daughter saw at the New England Aquarium. Parker thought understanding more about the way they moved could give us a better understanding of the human heart. Parker mimicked the stringrays’ anatomy to create a soft robot (“gold skeleton sandwiched between two silicone layers”) with a difference. This robot incorporated 200,000 heart cells (from rat embryos). The plan was for these cardiac cells to do the work of skeletal muscles (which they did) powered by a virus and optogenetics. In their report, Science magazine joked that the stringray’s speed is ”quite pathetic by real stingray standards” but quoted Princeton engineer Alexander Smits to make a final point “we’re getting to the point where there really is a fusion between biology and engineering”.

Robot Doctors, Robot Nurses and “Carebots”

Nurses at Beth Israel Deaconess Hospital in Boston are using a humanoid robot designed by SoftBank robotics to help them with scheduling - which even for humans is a pretty daunting and complex task. Researchers at MIT showed the robot exactly how nurses were doing the scheduling, which involved complex, highly coordinated actions, and after training the robot succeeded in the tasks 90% of the time. Humber River Hospital in Toronto has taken it several steps further as North America’s first fully digital hospital; SiliconANGLE describes the scene at Humber River: “In the hospital, you will find robots mingling amongst human staff, with robots responsible for mixing the correct dosage of chemotherapy drugs, to transporting meals, medications, and linen”.

The Atlantic reports that doctors as well as nurses are being replaced by robots in countries where doctors are hard to come by. “In Brazil and India, machines are already starting to do primary care, because there’s no labor to do it,” says Robert Kocher, an internist, a veteran of McKinsey consulting, and a former adviser to the Obama administration. “They may be better than doctors. Mathematically, they will follow evidence—and they’re much more likely to be right.”

By 2025, Japan will have a shortage of 1 million caregivers for their aging population; to solve this issue Japanese companies are leading the world in the production of carebots. Emerging tech thought leader Alec Ross described the state of Japan’s carebots industry in a LinkedIn Pulse post earlier this year: “Japan already leads the world in robotics, operating 310,000 of the 1.4 million industrial robots in existence across the world…In 2013, the Japanese government granted $24.6 million to companies focusing on eldercare robotics. Japan’s prominent Ministry of Economy, Trade, and Industry chose 24 companies in May 2013 to receive subsidies covering one-half to two-thirds of the R&D costs for nursing care robots.”

Boston as Robotics Hub

Along with the incredible 3-D printed and bioengineered robots that The Wyss Institute has given us this year, there is evidence that biotech hub Boston is also growing as a robotics hub. Tom Ryden, executive Director of Mass Robotics, describes the current vibe in Boston Business Journal earlier this month: “(Massachusetts robotics companies are) very open in sharing so they want to see all companies grow,” he said. “They realize it’s a ‘rising tide floats all boats’ type of thought…Not not only do we have some of the early companies like iRobot that really started this kind of revolution, but there are so many universities that have robotics programs or are doing robotics research in the Greater Boston area. That makes for a great idea generator, so it just kind of snowballed and built a great community.”

Last year CNBC reported that in Massachusetts: “more than 3,200 people (were) employed in the robotics industry. More than $200 million has been invested in Massachusetts robotics companies since 2008, and annual sales of robotics manufactured in state have topped nearly $2 billion.” The Mass Technology Research Council has an entire report devoted to “The Massachusetts Robotics Revolution” which you can download here.

Interested in hearing more about innovations in the intersection of bioengineering and medicine? Download our report here. And don't forget to follow Biotech Week Boston on Twitter for news on innovation in biotech and medicine. Each year passionate scientists and innovators converge on Boston to share ground breaking data, research and ideas - don't miss our next event in September 2017!

|

Share this article with your social network, just click below to share now!

|

|

|